Why are PLA, PBAT and starch chosen as raw materials for biodegradable plastic bags?

As the problem of “white pollution” becomes more and more serious, countries around the world have introduced more stringent policies to restrict plastic bags. Nowadays, biodegradable plastic bags are widely used in major supermarkets and shopping centers. After careful observation, it is not difficult to find that almost all of these biodegradable plastic bags are mainly made of PBAT+PLA+corn starch. Therefore, what are the unique advantages of the combination of PBAT, PLA and corn starch?

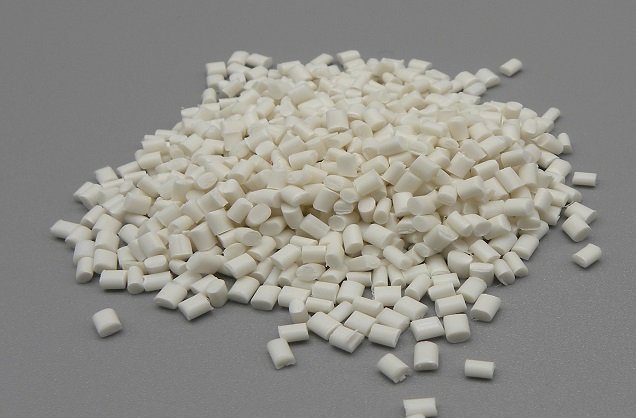

1、PLA (Polylactic Acid)

Polylactic acid (PLA) is made from the polymerization of plant-derived lactic acid. Under composting conditions (high temperature, high humidity, rich microorganisms), it can be completely decomposed into carbon dioxide (CO₂) and water (H₂O) by fungi, bacteria and other microorganisms, with a degradation cycle of 3-6 months, and with non-toxicity in degradation products.

Rigidity and heat resistance of PLA

High hardness, heat resistance (can withstand 60-90 ℃ temperature), suitable for the production of bags that require a certain degree of stiffness (such as take-away lunch box bags), but pure PLA toughness is not enough, easy to crack.

Plant-based properties of PLA

The raw material lactic acid comes from the fermentation of corn, sugar cane and other crops, which is a renewable resource and reduces dependence on fossil raw materials such as petroleum, which is in line with the concept of circular economy.

Scale production reduces cost

PLA and PBAT have been industrially produced, and with the expansion of production capacity (e.g., the global PLA production capacity will increase from about 150,000 tons in 2010 to more than 1 million tons in 2023), the price is gradually decreasing (the price of PLA has dropped from about 30,000 yuan/ton to 15,000-20,000 yuan/ton), and it is close to the level of traditional plastics.

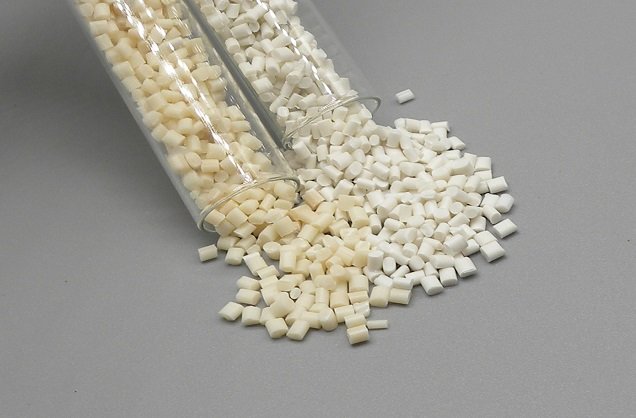

2、PBAT (Polybutylene Adipate / Terephthalate)

PBAT is an aliphatic-aromatic copolyester with good biocompatibility and degradability. In soil, seawater or compost environment, it can be gradually decomposed by microorganisms into small molecules, and ultimately converted into CO₂ and water. The degradation process is slower than PLA (usually takes 6-12 months), but the flexibility is better.

Flexibility and ductility of PBAT

PBAT has good elasticity and tensile resistance, similar to the feel of traditional polyethylene (PE) plastic bags, which can make up for the brittleness of PLA, and the blending of the two can improve the tear resistance and durability of the bags.

Partial Renewability of PBAT

Although the production of PBAT still relies on petroleum-based raw materials (e.g. adipic acid, terephthalic acid), some companies have developed bio-based PBAT (e.g. bio-based adipic acid as raw material), which is expected to enhance sustainability in the future.

Scale production reduces cost

PLA and PBAT have been industrially produced, and with the expansion of production capacity (e.g., the global PLA production capacity will increase from about 150,000 tons in 2010 to more than 1 million tons in 2023), the price is gradually decreasing (the price of PLA has dropped from about 30,000 yuan/ton to 15,000-20,000 yuan/ton), and it is close to the level of traditional plastics.

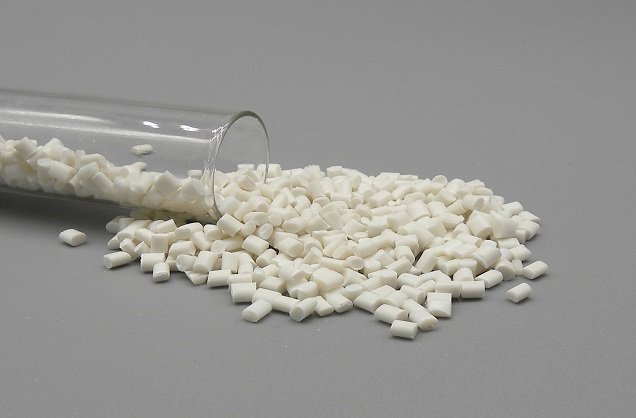

3、Starch

Natural polymer materials, from a wide range of sources (such as corn, potato, wheat, etc.), can be rapidly decomposed by microbial secretion of amylase, fast degradation, but when used alone, the mechanical properties of the poor (easy to brittle, low strength), often mixed with PLA, PBAT to improve performance.

Cost and synergy of starch

Adding starch as a filler to the PLA/PBAT system reduces the overall cost while increasing the degradation rate of the material (starch breaks down before the polymer, forming a porous structure that accelerates microbial attack on the PLA/PBAT).

Natural renewability of starch

Wide range of sources and low cost, the use of agricultural waste (such as starch from corn stalks) can also reduce resource waste.

Economics of starch

As a cheap filler (price about 0.3-0.5 million Yuan/ton), it can significantly reduce the cost of composites, e.g. PLA/PBAT/starch blends with 30%-50% starch content can reduce the cost by 20%-40% compared to pure PLA.

Significant progress in PBAT/s

Significant progress in PBAT/s

PLA/PBAT composite film degrad

PLA/PBAT composite film degrad

A New Choice for Takeaway Pack

A New Choice for Takeaway Pack

Significant progress in PBAT+s

Significant progress in PBAT+s

CONTACT

Add: Room 4006, No.1 Helong Yiheng Road, Baiyun District, Guangzhou City

Tel: +8613450255948

Wechat : +86-13450255948

Fax: +86-13450255948

E-mail: 13450255948@163.com