“PLA vs PBAT vs Starch-based? An in-depth look at the true nature of the 3 “biodegradable” plastic bag materials!

You buy the “environmental protection bag” may really pollute the environment?

In our daily life, those “biodegradable” plastic bags costing 3-5 RMB are always being utilized infinitely every day. However, according to the China Plastic Industry Association (CPIA) 2024 report, 68% of the “biodegradable” plastic bags on the market have a lot of false advertising! In today's article, we will use actual monitoring data and real cases, for you to understand the real face of PLA, PBAT and starch-based three “degradable” materials!

3 kinds of “degradable” material comparison depth better reflect the nature of environmental protection!

1, PLA (polylactic acid): “pseudo-environmental”

Polylactic acid (PLA) is a corn starch or sugar cane and other plant materials fermented into bioplastics. It has good transparency and mechanical properties, widely used in food packaging, shopping bags and other fields.

The main advantage of PLA is that it is highly biodegradable and can be decomposed within a few months under industrial composting conditions. The source is renewable resources, reducing dependence on petroleum resources, and is non-toxic and harmless, meeting food safety standards. However, it requires a specific composting environment for complete degradation, and the degradation rate is slower under normal natural conditions. Costs are slightly higher than traditional plastics, and thermal properties are limited and easily deformed.

Raw material truth: each ton consumes 2.7 tons of corn, equivalent to the annual output of 5 acres of land; the annual consumption of China's PLA industry can solve the problem of 2 million people's hunger.

2, PBAT: “microplastic crisis”

Poly adipic acid - terephthalate (PBAT) is a flexible, good ductility biodegradable plastics, often used in combination with PLA and other materials to enhance the toughness of plastic bags.

PBAT has high elasticity and is suitable for making plastic bags with high durability. It also has good biodegradability and can be rapidly degraded under industrial composting conditions. The degradation process can be combined with other bioplastics to improve performance. However, compared with PLA, the production cost is higher than ordinary plastics. The degradation conditions are more stringent and require industrial composting facilities to degrade.

After testing PBAT plastic bags amazing data can be seen, PBAT plastic bags in the early stages of degradation will produce 0.5-2mm micro-plastic particles, each square meter of film will release 1200 + micro-plastic particles, after long-term use, these micro-plastic particles will be through the food chain into the human body, will cause physical harm.

2024 Plastic industry chaos:

As can be seen from the sampling data, plastic bags 41% of PBAT's products are mixed with ordinary PE material, 23% of the sample degradation additive content is less than 50% of the claim, there are also various well-known brands are false rumors of the phenomenon of being punished. Therefore, PBAT plastic products also exist in the nature of environmental protection?

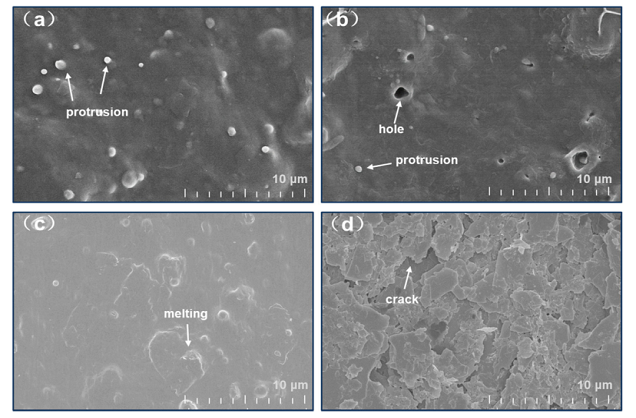

PBAT microplastic electron micrograph:

3, starch-based: the worst “pseudo-environmental”

Starch-based plastic bags are mainly made of starch after modification and processing, with lower production costs, suitable for large-scale use.

Starch-based plastic bags in the production of low production costs, easy to promote. Mainly from corn, potatoes and other starch-based plants, raw materials are abundant. Biodegradation can be realized under specific conditions, and the degradation cycle is long (generally about 1-2 years).

Found by the results of sampling most products:

The starch content of starch-based products is 40-70%, while the actual content is 8-35%, some products are also detected with banned plasticizers, and all of these PBAT plastic bags have residual plastic skeletons in the degradation process.

How to recognize the real and fake biological “biodegradable” 2024 latest guide!

1, check the bag logo: GB/T38082-2024 certification, double J compost logo.

2, certification mark:

International: Ok Compost (industrial compost), Marine Degradable (marine degradation).

Domestic: GB/T 19277.1 (controlled compost degradation), GB/T 20197 (degradable materials classification).

3, touch the product texture: PAL surface is usually ceramic smooth, PBAT has rubber elasticity. Starch-based image is rough particles.

4, burning product test: PAL burning will produce a strong corn sugar flavor and white ash; PBAT burning will produce candle smell and black smoke; starch-based burning will produce a burnt taste and dripping plastic.

Material Cost Price easonable Price Profit Red Line

PLA 28RMB/kg <=35RMB/pc >50RMB

PBAT 22RMB/kg <=30RMB/pc >40RMB

Starch-based 9RMB/kg <=15/pc >25RMB

Significant progress in PBAT/s

Significant progress in PBAT/s

PLA/PBAT composite film degrad

PLA/PBAT composite film degrad

A New Choice for Takeaway Pack

A New Choice for Takeaway Pack

Significant progress in PBAT+s

Significant progress in PBAT+s

CONTACT

Add: Room 4006, No.1 Helong Yiheng Road, Baiyun District, Guangzhou City

Tel: +8613450255948

Wechat : +86-13450255948

Fax: +86-13450255948

E-mail: 13450255948@163.com